Release time:2024-05-06

Injection moldingThe defect of insufficient filling during molding is that the mold is not full. So what is the reason for this defect, how can we find the reason for this defect, and how to solve it?

1. If we set the injection volume of the injection molding machine to the maximum during injection molding, the defect of insufficient filling will not be improved, that is, the problem of injection pressure or temperature.

2. When the measurement is set to the maximum value, the temperature and pressure are judged by experience, and there is no abnormality. If there is insufficient filling, it is mostly due to the setting of the injection volume of the injection molding machine.

3. Plastic materials have a countercurrent relationship, which often leads to incomplete filling. In order to prevent reverse flow, a check ring should be installed. PE, ABS, PP, PA and other low viscosity resins must be equipped with check rings.

4. Resin temperature will also affect the dissatisfaction of mold filling. If the temperature is too low, the viscosity is too high and the fluidity is poor, sometimes resulting in incomplete filling of injection mold.

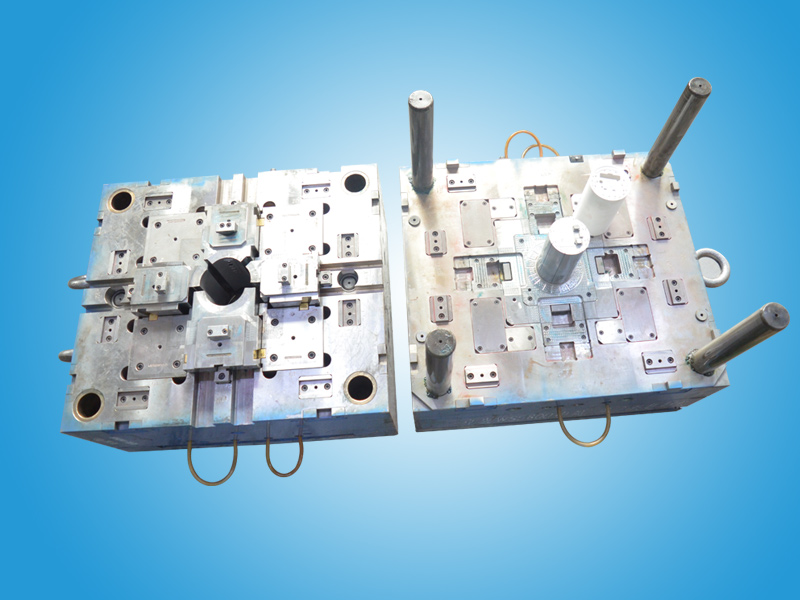

5. Plastic injection mold will also affect the filling of plastic materials.

If the channel area of the molten resin runner gate and main runner in the mold is very small, it will block the pressure and hinder the flow of plastic. The corresponding mold should be designed according to the characteristics of the resin used. If the same mold is used for multiple plastics, it is difficult to obtain the same effect.

In addition, for high viscosity plastics, when the injection molding accuracy is required to be high, the mold temperature needs to be increased, which is conducive to the fluidity of plastics, so it has a great relationship with the mold temperature.

6. There are other aspects, such as the injection speed is too slow, or the pressure holding cannot be improved due to the occurrence of longitudinal flash, which will also cause the phenomenon of insufficient mold filling.